CASE STUDY

Case 1

Achieved the automation of counting and cartoning system from manual operation

OUTLINE

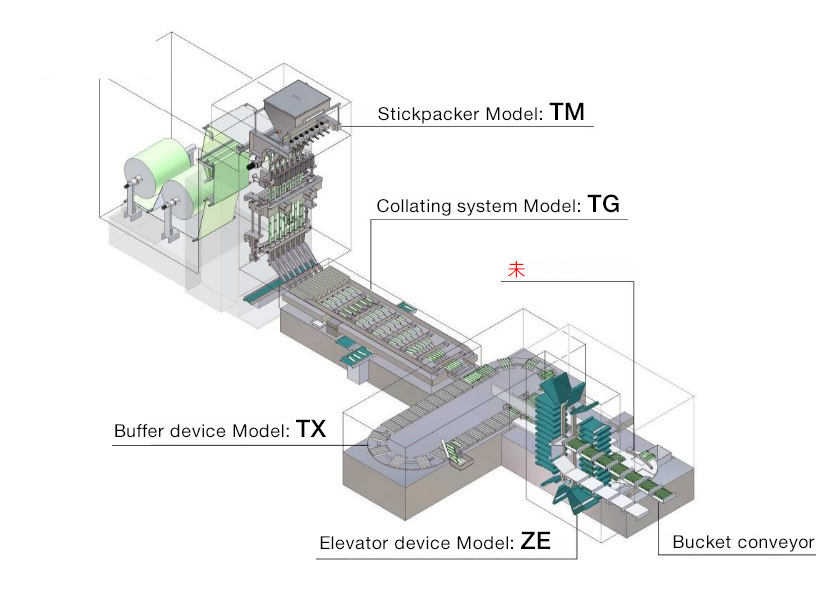

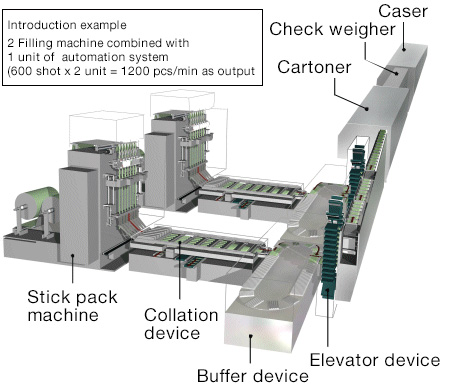

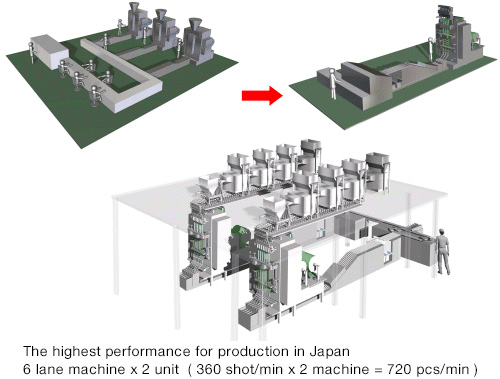

As multi lane stick packaging machines become more popular and faster, the manual counting and collating work was the issue as the labor cost or operational error.

Therefore, Toyo has developed automated equipment for automation counts into secondary packaging, and has achieved further productivity improvements, space savings, and manpower savings for the entire line.

POINT

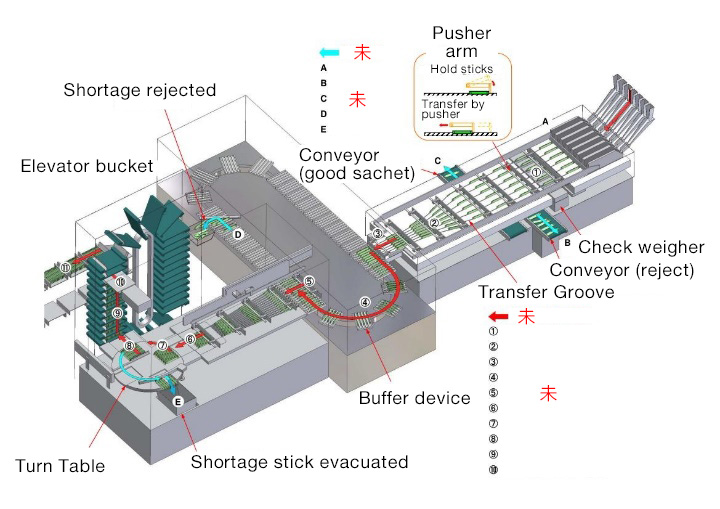

- A system that measures the weight of each lane during conveying and automatically adjusts the filling amount after analyzing the data (feedback system) by check weigher.

- Incorporating a one-touch sampling device and considering the operational efficiency of the entire line.

- Install a buffer device, making it easy to change counts with just a few parts replacements, making lot changes easy.

- By intermittent transportation inside the cover, products are prevented from being damaged or contaminated by the atmospheric environment during transportation.

- Transfer operation is stable, and it is transported to secondary packaging in an aligned condition.

- By connecting two machines into one line, we can further improve the productivity of the entire line, save space and save labor cost.

It has become a standard automatic production system now for carton packaging for major domestic and overseas pharmaceutical manufacturers, and has been highly praised for decades for its combination of high productivity and quality stability.

Case 2

One filling machine for different types of products (Assorted product)

OUTLINE

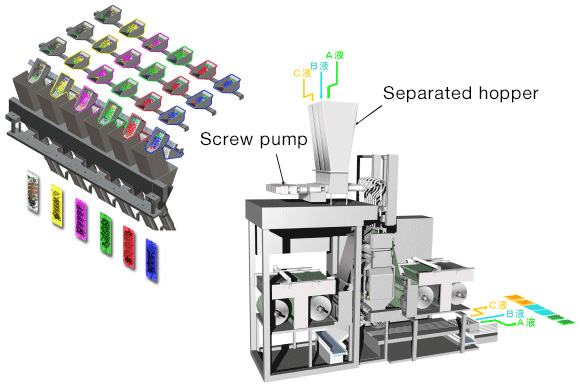

Assorted products allow you to enjoy different types of taste at once, but in the past, each type was produced using one filling machine or by changing the filling machine each time.

Toyo machine solved the problems from the users as “ using several single lane machine ” or “ taking time and effort for cleaning and setting up every time for changing the product…” etc…by our multi lane machine for assorted product.

POINT

- Developed an assortment packaging machine by our important know-how of multi lane filling machines.

- Saving the space by replacement of several single lane machine to our 1 multi lane machine.

- Unlike single lane filling machines, there is no need to change the machine type or clean it every time you change lots.

Example: When packaging ingredients for instant soup, different types of ingredients can be packed by multi lane using one filling machine. - Contributing to labor and space savings by our automation system.

By using our know-how with multi lane filling machines and developing an individual filling and supply method, we created an assortment packaging machine to the world.

Case 3

Adding value to packaging

OUTLINE

We respond to customers' requests for not only packaging things, but also differentiating them with functionality and appearance.

We developed R-cut (=Rounded corner cutter) of stick packaging for the first time in the world in stick packaging

POINT

- Universal design that prevents corners from getting stuck in your hands when using

- Stylish packaging that looks luxurious

- Developed jointly with a knife manufacturer to achieve stable cutting quality.

Stick packaging for liquids and viscous substances that is a further development of R-cut

Bottle mouth cut (Patented design)

POINT

- Individually packaged liquids and viscous substances for “splash-free,” “easy to open,” “easy to drink,” and “easy to carry.”

- The four corners and spout are rounded to prevent injury to your hands and mouth.

- Best-seller mainly for individual packaging of liquid medicines.

Added a safety feature that further improves the bottle mouth cut.

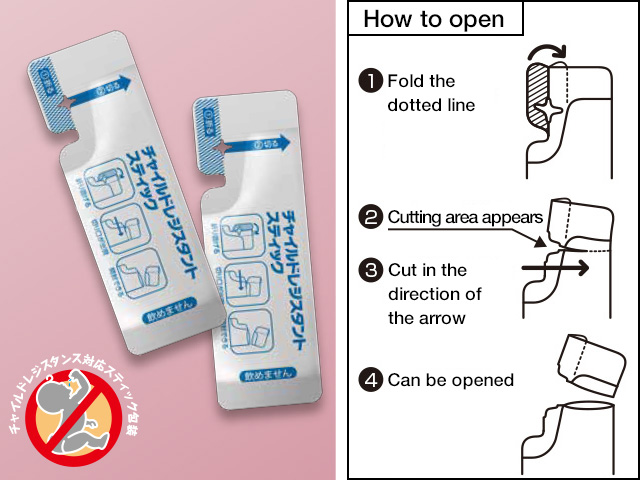

Child resistance design

POINT

- Designed with safety features in the packaging to prevent children from accidentally ingesting alcoholic beverages, etc., making them difficult to open.

- Added folding action when opening to prevent accidental ingestion by elderly people and children.

Toyo machine is a packaging machinery manufacturer, and we work together with our customers to consider what kind of packaging should be used to make consumers even more happy, and we continue to pursue better packaging forms and designs with the customers.